Introduction

The sterilization of medical devices is a cornerstone of infection control and patient safety within the healthcare sector. As the industry grapples with evolving challenges and increasing demand for effective sterilization solutions, understanding the various methods available is essential. From the widely utilized ethylene oxide (EtO) to steam sterilization, each technique presents unique advantages and challenges.

With an estimated 50,000 devices relying on EtO in 2024 and significant market growth projected across regions, the implications of these sterilization methods are far-reaching. This article delves into the intricacies of sterilization techniques, regulatory considerations, and emerging innovations, providing a comprehensive overview that underscores the importance of maintaining high standards in medical device sterilization.

Overview of Sterilization Methods for Medical Devices

The sterilization methods for medical devices used in sanitizing healthcare instruments are crucial in preventing infections and ensuring patient safety. In 2024, approximately 50,000 medical devices will depend solely on ethylene oxide (EtO) for disinfection, highlighting the essential role of this chemical process in the healthcare sector. The techniques employed can be classified into physical, chemical, and biological approaches used in sterilization methods for medical devices.

-

Physical techniques include:

- Heat sterilization, such as autoclaving

- Radiation, both of which effectively eliminate pathogens by applying extreme temperatures or high-energy radiation.

-

Chemical techniques encompass the use of:

- Gases like ethylene oxide

- Liquid disinfectants, each offering distinct benefits and limitations. For instance, while EtO is highly effective for heat-sensitive materials, it requires meticulous handling due to its toxicity.

Grasping the applications of sterilization methods for medical devices in different clinical settings is vital, particularly considering the increasing occurrence of chronic illnesses—documented at 60% among adult Americans by the National Association of Chronic Diseases Directors in April 2022. North America is anticipated to hold a 35.43% share of the equipment market for disinfection in 2024, propelled by an aging demographic and rising healthcare spending, emphasizing the importance of efficient disinfection techniques. Furthermore, the Middle East and Africa (MEA) disinfection equipment market is experiencing growth due to increased awareness about sanitization and the prevalence of chronic diseases, which is expected to drive the entry of major players into the market.

This overview lays the groundwork for a more comprehensive examination of sterilization methods for medical devices and their implications in clinical settings, particularly as recent news highlights support for chronic disease entrepreneurs, reflecting the ongoing relevance of these issues in healthcare.

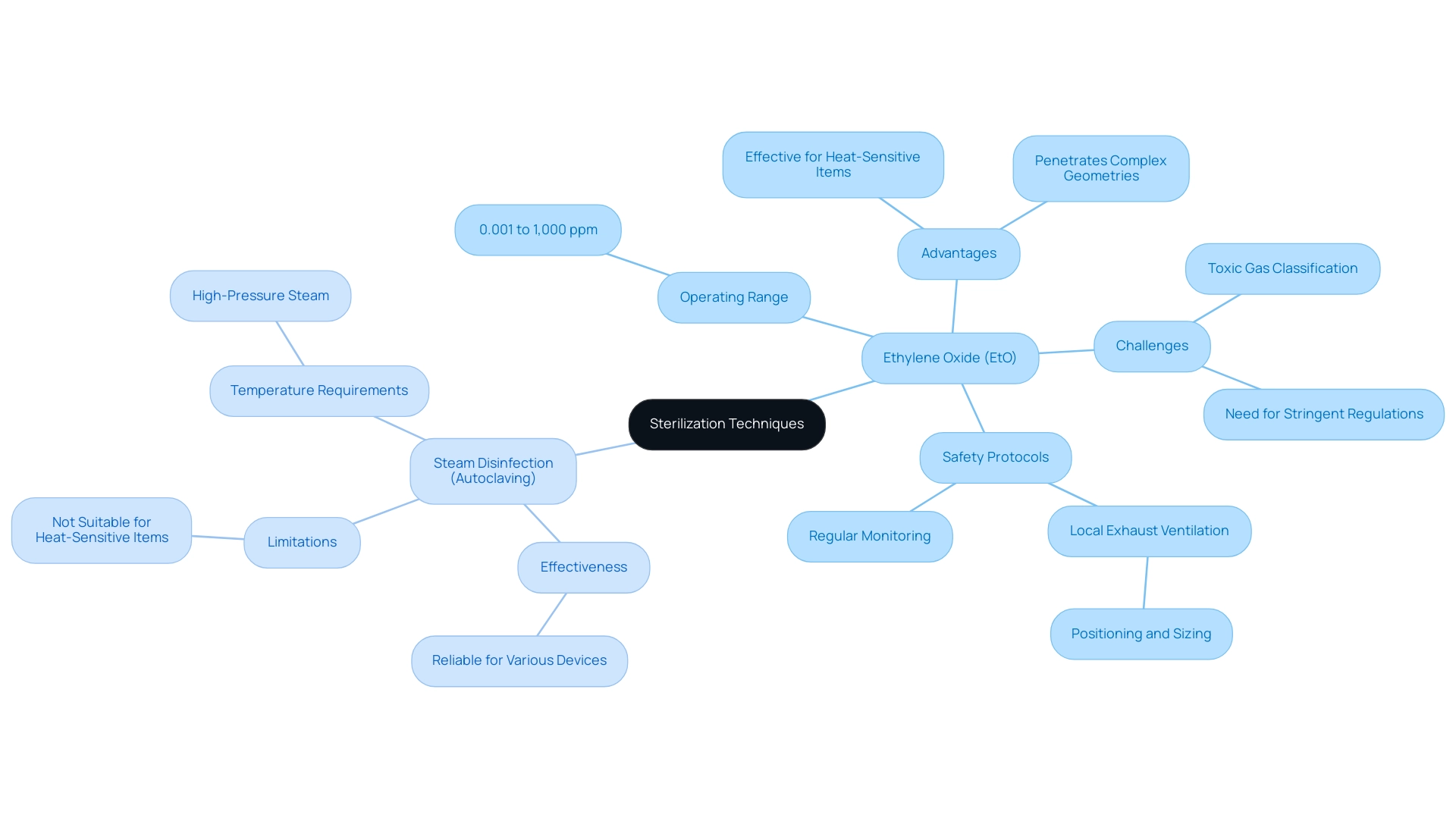

Commonly Used Sterilization Techniques: Ethylene Oxide and Steam

Ethylene Oxide (EtO) sterilization is a crucial technique that falls under the sterilization methods for medical devices, ensuring the sterility of heat-sensitive items. Operating within a working range of 0.001 to 1,000 ppm, EtO is particularly advantageous for sterilizing plastics and electronic components due to its low-temperature requirements. However, this approach is not without its challenges; EtO is classified as a toxic gas, necessitating stringent regulations and safety protocols to mitigate exposure risks.

Local exhaust ventilation systems, which must be adequately positioned and sized, play a crucial role in capturing EtO emissions, especially when the sterilizer door is first opened. According to Leidel et al., “The most reasonable, efficient sampling strategy is to sample the worker with the highest risk of exposure,” further emphasizing the importance of monitoring in environments where EtO is utilized. Regular oversight of sterilizers and work settings is essential for guaranteeing effective control strategies against EtO exposure, as emphasized in case studies on monitoring and control practices.

In contrast, steam disinfection, or autoclaving, employs high-pressure steam to achieve sanitation, making it highly effective for a broad range of devices that can withstand elevated temperatures. Both sterilization methods for medical devices offer distinct benefits and drawbacks; steam treatment is recognized for its reliability and effectiveness, while EtO's unparalleled capability to penetrate complex geometries is noteworthy. However, the challenges associated with EtO disinfection, including the need for careful handling and strict adherence to safety protocols, must be weighed against the benefits.

As healthcare providers navigate the complexities of sanitation options, understanding sterilization methods for medical devices is critical for ensuring patient safety and complying with regulatory standards.

Choosing the Right Sterilization Method for Different Medical Devices

The selection of appropriate sterilization methods for medical devices is significantly influenced by various essential elements, including material compatibility, instrument complexity, and compliance with regulatory standards. For instance, devices made from heat-sensitive materials often require chemical cleaning methods, such as Ethylene Oxide (EO), which are effective sterilization methods for medical devices that can achieve terminal sterility with minimal risk of damage. Andersen’s EO-Flexible Chamber Technology illustrates a dependable and effective gas cleansing technique, ensuring terminal sterility (10-6 SAL) and positioning it as one of the key sterilization methods for medical devices in infection prevention.

In contrast, instruments able to withstand higher temperatures are ideally suited for steam purification, one of the recognized sterilization methods for medical devices due to its efficacy and reliability. Furthermore, the application of 2% glutaraldehyde can be effective, necessitating a shorter exposure duration of only 20 minutes at 20°C, further emphasizing the significance of choosing suitable sterilization methods for medical devices. Dr. D.J. Weber, a consultant for Clorox and Germitec, emphasizes,

Understanding the characteristics of the materials involved is paramount in selecting the right disinfection method.

This insight emphasizes the necessity for manufacturers and researchers to navigate these complexities carefully to ensure that medical products not only meet safety standards but also utilize effective sterilization methods for medical devices to deliver optimal performance in clinical settings. Moreover, a randomized controlled trial carried out in 9 hospitals showed the effectiveness of UV-C (Tru-D) in decreasing MRSA, VRE, and CDI cases from 51.3 to 33.9 per 10,000 patient-days (p = .036), emphasizing the real-world impact of understanding different disinfection methods.

Staying informed about the latest protocols and trends in sanitation practices is crucial for healthcare providers and manufacturers alike, as these factors directly influence patient safety and equipment effectiveness.

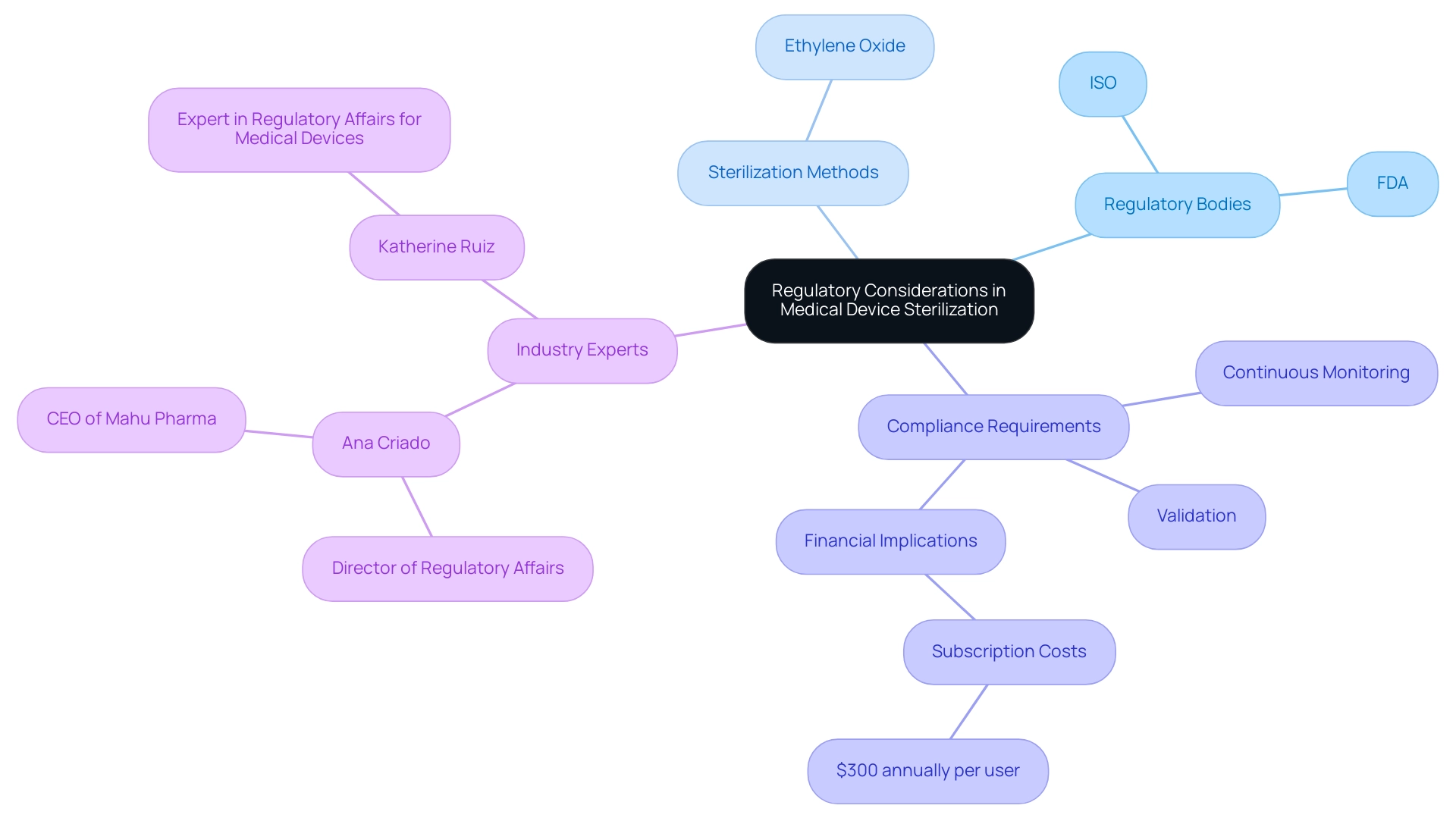

Regulatory Considerations and Safety in Medical Device Sterilization

Regulatory factors are crucial in the cleansing of healthcare instruments, with organizations like the FDA and ISO setting strict protocols that producers must follow to ensure safety and effectiveness. The use of Ethylene Oxide, in particular, is tightly regulated due to its associated health risks. This necessitates comprehensive validation and continuous monitoring to ensure compliance.

State health departments also play a critical role in inspecting healthcare facilities that utilize Ethylene Oxide for disinfection, thereby adding an additional layer of regulatory oversight. Dr. Scott Gottlieb, former FDA Commissioner, highlighted the significance of upholding efficient sterilization methods, stating,

The Agency is taking steps to prevent potential shortages of healthcare instruments and ensure safe and effective sterilization amid the shutdown of a large contract sterilization facility.

Furthermore, the FDA's recent guidance on the Transitional Enforcement Policy for Ethylene Oxide Sterilization Facility Changes seeks to address disruptions in sterile item processing related to sterilization methods for medical devices caused by operational changes at these facilities.

This policy specifically targets producers of Class III products, aiming to alleviate supply chain challenges and ensure sufficient availability of completed sterile healthcare items. The financial implications of compliance with the regulatory standards can also be significant; for instance, subscription costs for regulatory tools can reach $300 annually per user, underscoring the importance of adherence to guidelines. By following these regulations, manufacturers not only protect patient health but also bolster their credibility in the marketplace, reinforcing their commitment to safety and quality.

With experts like Ana Criado, Director of Regulatory Affairs and CEO of Mahu Pharma, who has extensive experience in Regulatory Affairs and cannabis regulation, and Katherine Ruiz, an expert in Regulatory Affairs for Medical Devices and In Vitro Diagnostics in Colombia, the industry can navigate these complexities more effectively. Ana's background in health economics and her role as a consultant further enhance her ability to address the regulatory challenges in sanitation standards.

Innovations and Future Trends in Medical Device Sterilization

The landscape of medical device purification is rapidly evolving, highlighted by significant innovations in sterilization methods for medical devices that promise to enhance safety and efficiency. Emerging decontamination technologies, such as plasma treatment and the use of supercritical carbon dioxide, are gaining recognition as viable alternatives to traditional sterilization methods for medical devices. These advancements not only alleviate safety issues linked to traditional agents but also simplify the overall disinfection process.

According to market analysis, the global sanitation products and services market was valued at approximately $13.7 billion in 2022 and is projected to reach $20 billion within the next five years, indicating a robust demand for innovative solutions. Furthermore, 510(k) holders typically do not need to submit a new 510(k) for changes related to sanitation facility adjustments, simplifying the regulatory pathway for adopting new technologies. In addition, four new technologies are currently progressing through the FDA's Innovation Challenge, showcasing ongoing advancements and regulatory support in the industry.

Despite this promising market outlook, the disinfection industry has faced challenges in adapting to these advancements, often hindered by established processes and the technical expertise required, leading to a backlog in disinfection services. Kate Stephenson, PhD, aptly notes that,

Sterilization tech companies fall clearly in the class of companies that are 'underappreciated, undervalued, and misunderstood'.

As professionals engaged in medical device research and development, it is imperative to stay abreast of these trends and innovations, which are expected to shape the future of sterilization methods in healthcare.

Conclusion

The sterilization of medical devices is a critical component of infection control and patient safety, with various methods offering distinct advantages and challenges. Ethylene oxide (EtO) and steam sterilization are among the most widely used techniques, each tailored to specific device materials and complexities. While EtO is indispensable for heat-sensitive devices, its toxic nature necessitates stringent safety protocols. In contrast, steam sterilization remains a reliable choice for heat-tolerant instruments, showcasing the importance of selecting the appropriate method based on material compatibility and regulatory standards.

Regulatory considerations play a significant role in the sterilization landscape, with agencies like the FDA and ISO enforcing guidelines to ensure the safety and efficacy of sterilization practices. Compliance with these regulations not only protects patient health but also enhances manufacturers' credibility in the market. The evolving nature of these regulations, particularly concerning EtO, reflects the industry's commitment to maintaining high standards amid operational challenges.

Looking to the future, innovations in sterilization methods, such as plasma sterilization and supercritical carbon dioxide, are poised to revolutionize the field. As the market for sterilization products and services expands, embracing these advancements will be crucial for healthcare providers and manufacturers alike. Staying informed about emerging technologies and regulatory updates will empower stakeholders to navigate the complexities of sterilization effectively, ultimately reinforcing their dedication to patient safety and care excellence.

Frequently Asked Questions

What are the main sterilization methods for medical devices?

The main sterilization methods for medical devices can be classified into physical, chemical, and biological approaches. Physical techniques include heat sterilization (such as autoclaving) and radiation, while chemical techniques involve gases like ethylene oxide (EtO) and liquid disinfectants.

How does ethylene oxide (EtO) work in sterilization?

Ethylene oxide (EtO) is a chemical sterilization method that is particularly effective for heat-sensitive materials. It operates within a range of 0.001 to 1,000 ppm and is advantageous for sterilizing plastics and electronic components due to its low-temperature requirements.

What are the benefits and challenges of using EtO for sterilization?

The benefits of using EtO include its effectiveness in sterilizing complex geometries and heat-sensitive items. However, it poses challenges due to its classification as a toxic gas, requiring stringent regulations and safety protocols to mitigate exposure risks.

What safety measures are necessary when using EtO?

Safety measures for using EtO include the installation of local exhaust ventilation systems to capture emissions, regular monitoring of sterilizers and work environments, and adherence to strict safety protocols to protect workers from exposure.

What is steam disinfection, and how does it compare to EtO?

Steam disinfection, or autoclaving, uses high-pressure steam to sanitize medical devices. It is highly effective for items that can withstand elevated temperatures. While steam treatment is reliable and effective, EtO is noted for its ability to penetrate complex geometries, making both methods suitable for different applications.

Why is understanding sterilization methods important in healthcare?

Understanding sterilization methods is critical for ensuring patient safety, preventing infections, and complying with regulatory standards, especially given the increasing prevalence of chronic illnesses among patients.

What is the projected market trend for disinfection equipment in North America?

North America is expected to hold a 35.43% share of the disinfection equipment market in 2024, driven by an aging population and increasing healthcare spending, highlighting the importance of efficient disinfection techniques.